The track rod end is fairly easy to replace and is covered in detail throughout the internet so I shan't dwell on that. The ball joint replacement is more challenging so I shall focus on that.

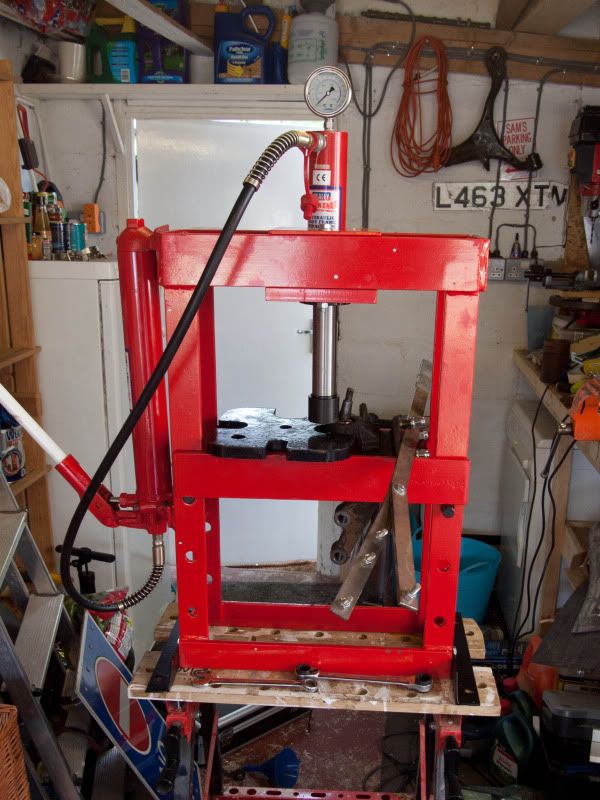

Honda don't supply ball joints separately. They supply knuckle assemblies with the ball joint fitted. This is costly, and requires a hydraulic press to fit the wheel bearing and hub. Wheel bearings are also costly! Ball joints can be found, however, and fitted to your knuckle using a hydraulic press. Sounds like a perfect excuse for buying a bad-ass tool!

It's a heavy bugger, 50kg! Here's the package freshly collected from the courier depot.

It comes in kit form, yay!

After assembly and commissioning of the press, I set about replacing the ball joints. This requires substantial disassembly of the front hub. The most important first step is loosening the hub nut. This nut is 'peened' to prevent it loosening, so it must first be 'un-peened' using a screwdriver, hammer or whatever you find works.

After this the nut can be loosened but beware, it is tight. I mean stupidly tight. I mean scottish-man's wallet tight. Seriously, I was using a 24" breaker bar and was a sweaty mess afterwards! The car must first be lifted and the front wheels removed. The plastic centre cap on the allots must be removed, the wheels refitted and the car lowered to the ground. Put the car in-gear and this should allow access to the hub nut and prevent the wheel from turning when you're wailing on it like a Ninja.

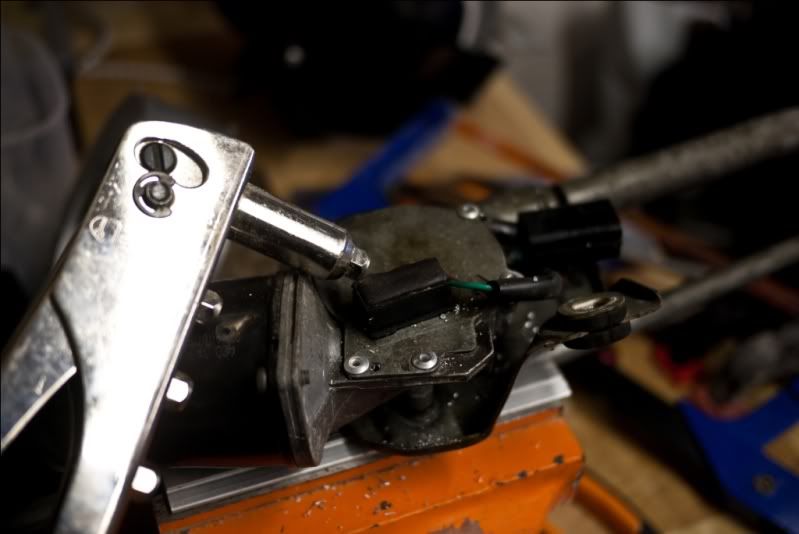

Once loose, the car can be put on axle stands and the hub assembly taken apart. Be careful not to pull on the drive shafts, they may need a tap to un-seat them from the hub. Remember to re-position the brake caliper which can be put on the ground without straining the hose. Also remove the abs sensor which can be quite stubborn.

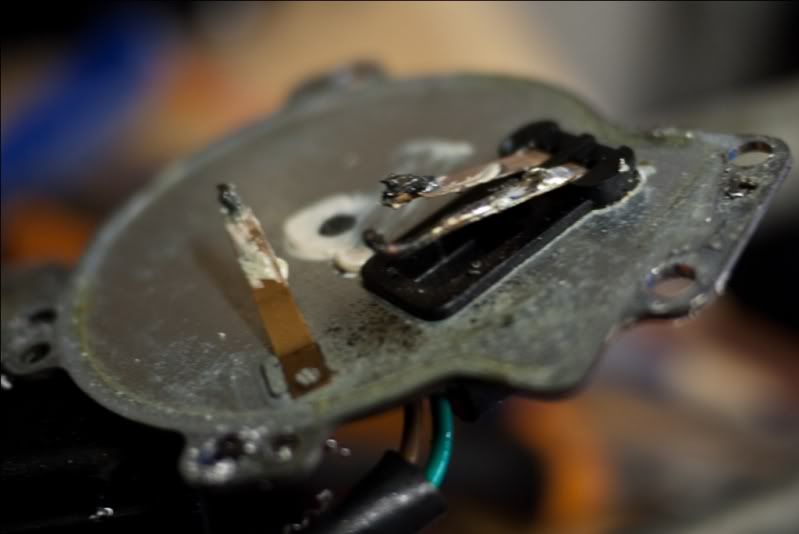

Once the knuckle is separated, it became clear that the disc guard had to be removed as it would just foul when using the hydraulic press. To remove it properly, the hub must be pressed out of the bearing but this was an unacceptable risk because removing or tampering with bearings often results in damage to the bearing. It was a tough call, but I decided to cut the dust guard off. There are also three screws which must be removed, but the hub gets in the way! I found vice-grips was the solution.

Then the fun began! The press was used to remove the ball joint. I won't even begin to describe how to do this because it's so dependent on what press you're using. Basically just use trial and error, cautiously, to find a method that works for you. It shouldn't take too much force to remove.

Once removed, clean up the knuckle as you don't want any dirt spoiling the fun when fitting the new one. I put the new ball joints in the freezer overnight. This makes the ball joint shrink slightly and easier to fit. Again, use trial and error CAUTIOUSLY! to fit the new ball joint. Also, make sure you have an appropriate size socket which means all the load is carried through the strong outer base of the ball joint rather than the vulnerable centre which could deform the ball joint casing. I found a 38mm impact socket from Halfrauds worked perfectly.

Once pressed into place, refit everything and revel in how much of a mechanical bad-ass you are!

Some pictures:

How it all looked to begin with.

Removed the brake caliper and disc.

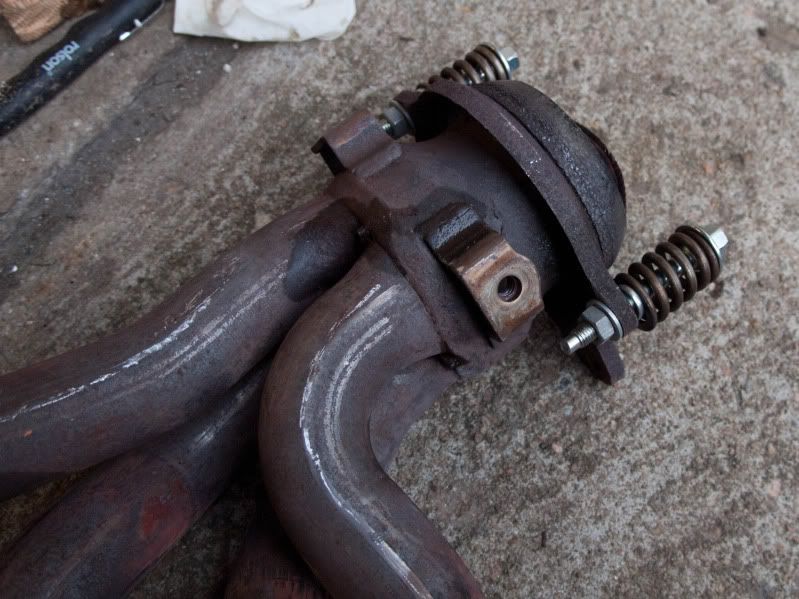

Knuckle removed from the car. Unfortunately the lower ball joint just would not split so I had to remove the lower control arm / wishbone too and separate it off the car.

Using the hydraulic press to remove the defective ball joint.

A picture of the hydraulic press. I opted for a Sealey 10Te press. It was a bit more expensive than a no-name ebay special, but these things are really powerful (read: dangerous) and I don't think it's worth skimping on. Also, the Sealey has a gauge which is nice.

Obligatory old vs. new. The new one is frosted because it's been in the freezer!

New one fitted to the knuckle. Ace!

Another view. Don't you just love shiny newness?!

All back together. Still shiny! Don't forget to fit the split pin - I fitted mine after this picture was taken.

Finally, I wanted to take a picture of the splined end of the driveshaft. The colours are really nice. This is different types of oxidation, promoted by high temperatures. I'm not sure if this heat has been generated during driving or if it's indicative of heat treatment during manufacture (used to temper the shaft and make it 'stronger') but it sure looks nice!

Also a shot showing the old vs. new for the track rod ends.