So anyway, threw on jeans and answered the door topless - unfortunately it wasn't the post girl of my dreams, but a very nice post man who was completely unperturbed by my get-up; I guess he gets that a lot...

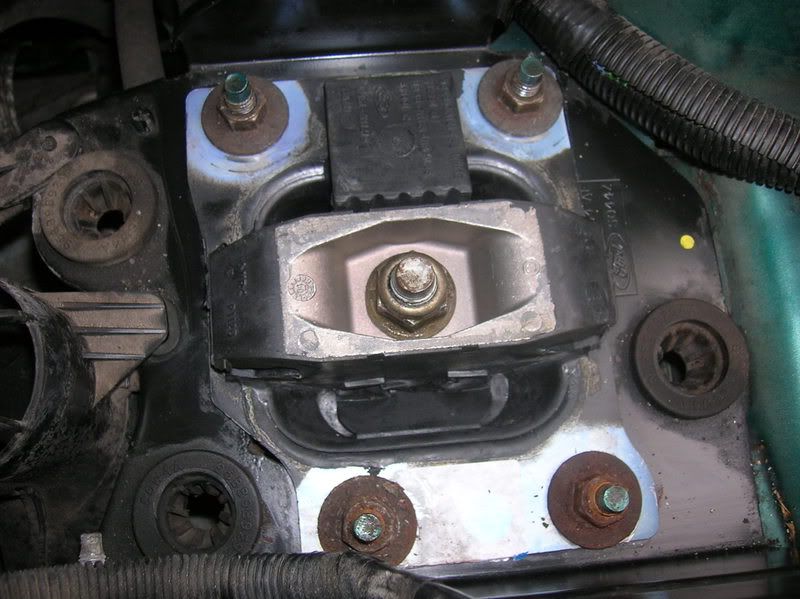

Anyway, first job as always is to check the part is the same or similar to the old one.

Now try to loosen the lock nut on the track arm. This is incredibly tight and the corrosion doesn't help. There are flats on the track rod end which you can get on with a spanner to hold it in place. Unfortunately when I did this, the entire track arm rotated with the lock nut but at least this freed the track rod end.

Next job is to undo the nut that holds the ball joint onto the steering knuckle. This is again incredibly tight and very prone to rounding off due to corrosion. I decided to hammer on a socket that was just too small. Then plenty of elbow grease via the breaker bar and it came loose. Then there is the challenge of getting the nut out of the socket!

This next bit was my favourite. Get the ball joint separator and make sure it is seated properly - you might need to wiggle it into place (like all the best things in life). Tighten the bolt until BAM! the ball joint pops out. Very satisfying!

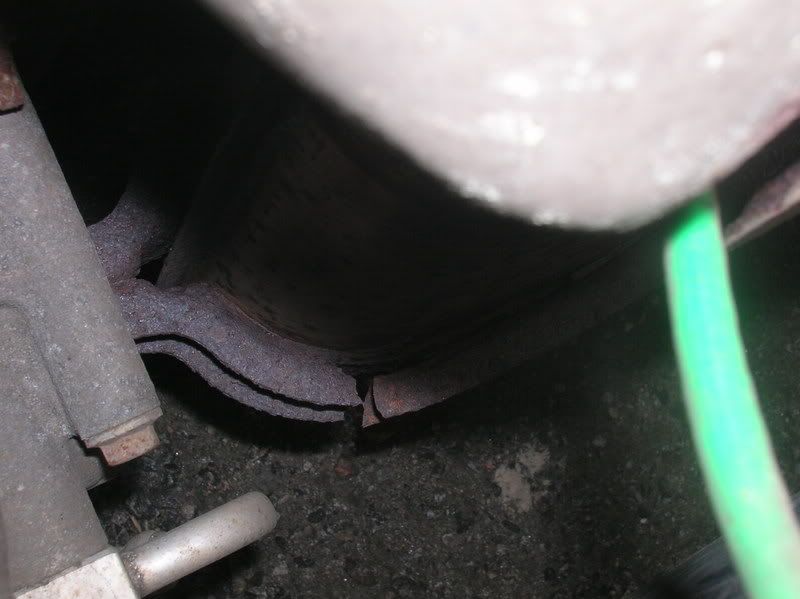

A quick look confirms that the old one is indeed borked!

Remove the old one, counting how many turns until it comes off, because that'll give you the best starting point for the tracking. Once it is off, I set about loosening the stubborn lock nut. Holding onto the track arm with vice grips seems savage but I don't know how else I'd have done it. Also, I brought the lock nut out rather than in because the threads were too corroded to let the lock nut move far in the other direction. Once loose, get a wire brush and clean the threads as best you can before applying some copper grease.

Now get the new track rod end and screw it on the same number of turns the old one required to come off. Fit the ball joint into place and tighten everything up. An allen key will probably be required to stop the threads on the ball joint rotating with the nut.

Get everything nice and tight and admire.

Just got back from the Garage, tracking only cost £25. I can't tell yet but the short drive to and from the garage seemed to be clunk free and the steering certainly feels a bit more positive now. Hardly surprising considering the state of that track rod end!

Quick Update: The clunk has gone!