The anti-roll bar runs between each front wheel, but curves up over the exhaust down-pipe in the middle of the car. This makes removal impossible without dropping the exhaust system to provide clearance. The down-pipe uses two spring-bolts to connect to the exhaust manifold and due to the heat these are subjected to, they were significantly corroded. Unfortunately upon removal, one of the bolts threads were stripped, the other sheared off in-situ. Gutted!

I did a bit of chin-scratching trying to decide what to do. The flange nut threads were badly damaged but the nuts could not be replaced because they were permanently connected to the exhaust manifold. What to do?

Eventually I decided to order new spring bolts from Honda and go through the hassle of removing the exhaust manifold and cutting off the captive nuts. Once these were removed, I could use normal replacement nuts which should make any future issues a lot simpler to sort out!

Removing the exhaust manifold turned out to be easier than I expect with most of the bolts still in reasonable shape considering the heat they have been subjected to. Clearance for removing the manifold from the engine bay was the most difficult thing, requiring the repositioning of some of the air-con pipework and ancillaries.

Once all back together all is fine! In fact, the engine sounds quieter at low revs / high load which suggests that the old exhaust bolts had loosened off. Here's a few pictures.

Obligatory old vs new exhaust bolt. The old one has stripped threads, extensive corrosion and is even bent out of shape!

The thread on the captive nut was also stripped, necessitating manifold removal...

The other exhaust bolts caused even more problems, shearing off when I tried to remove it...

Once the exhaust manifold had been removed, I cut off the captive nuts with a hacksaw.

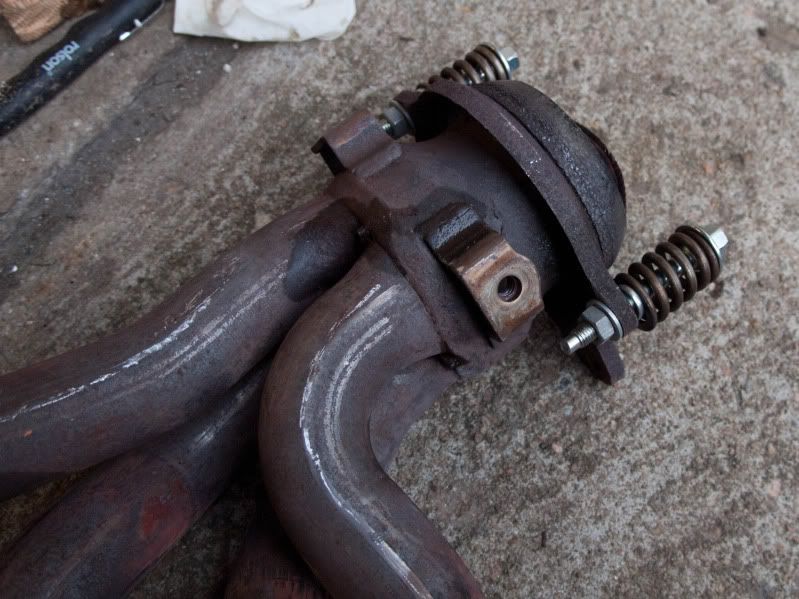

Picture shows the new arrangement used to connect the exhaust down-pipe and manifold.