Well upon closer inspection, it appears that this 'road grime' has come from a corroded oil cooler pipe which just so happened to spring a leak that sprayed the entire front hub in oil!

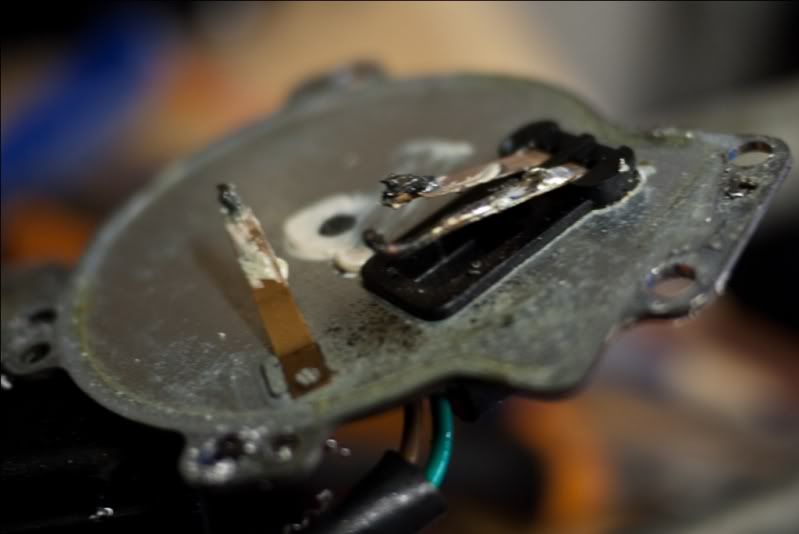

Here's the slimy remnants:

I have ordered new pipes, new front discs and pads, new oil filter and new oil. I'm not going to enjoy getting messy with this one, I just know it.

Update 1 (31/12/10)

I managed to get the removal work done today. I multi-tasked by draining the oil, then soaking the messy drivers side hub with degreaser whilst setting about removing the passengers side brakes.

Here's a picture of the oily side soaking with some degreaser that had a lovely citrus smell!!

Passenger side hub with caliper removed. This was incredibly difficult to remove partly due to the wear lip on the edge of the disc and partly because the car is old and everything was very tight.

Old pads.

The old disc proved very reluctant to budge. I had to resort to violence and even then it took a good 5 minutes.

The dust cover was badly corroded and had to go.

Having cleaned everything, I reassemble whilst I'm waiting on parts arriving in the post.

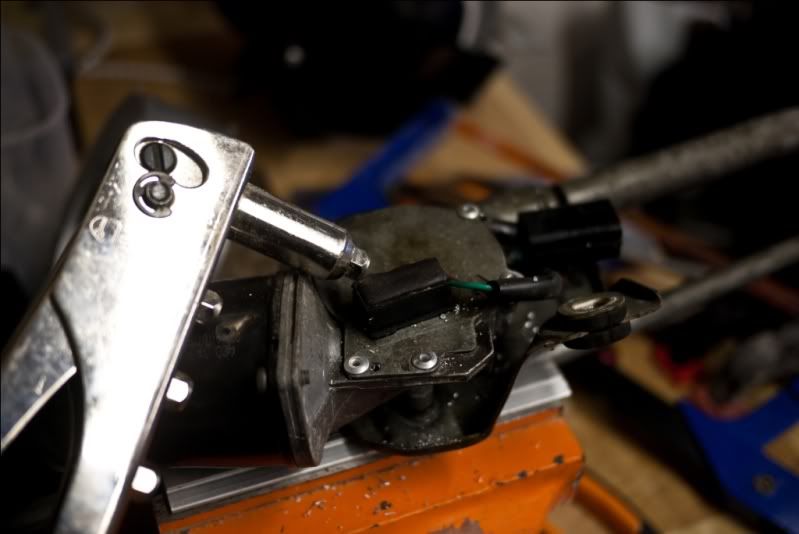

I then repeated the procedure on the drivers side. This was more difficult as two bolts holding the caliper in place had rounded off. I had little option but to take a slightly smaller imperial socket and fit it over the rounded bolt using the sledgehammer. Luckily they both came free and I managed to clean things up and put it back together again. I left the imperial sockets in place for now.

Now I removed the oil cooler pipes. These were very stiff too. Once removed I cut the ends off, crimped them then put them back in place to stop any debris getting into the oil system.

And finally here's a shot of the offending piece of pipe with the two small holes clearly visible.